PreciseFlex 3400

Payload: 3 kg | Horizontal reach: 588 mm

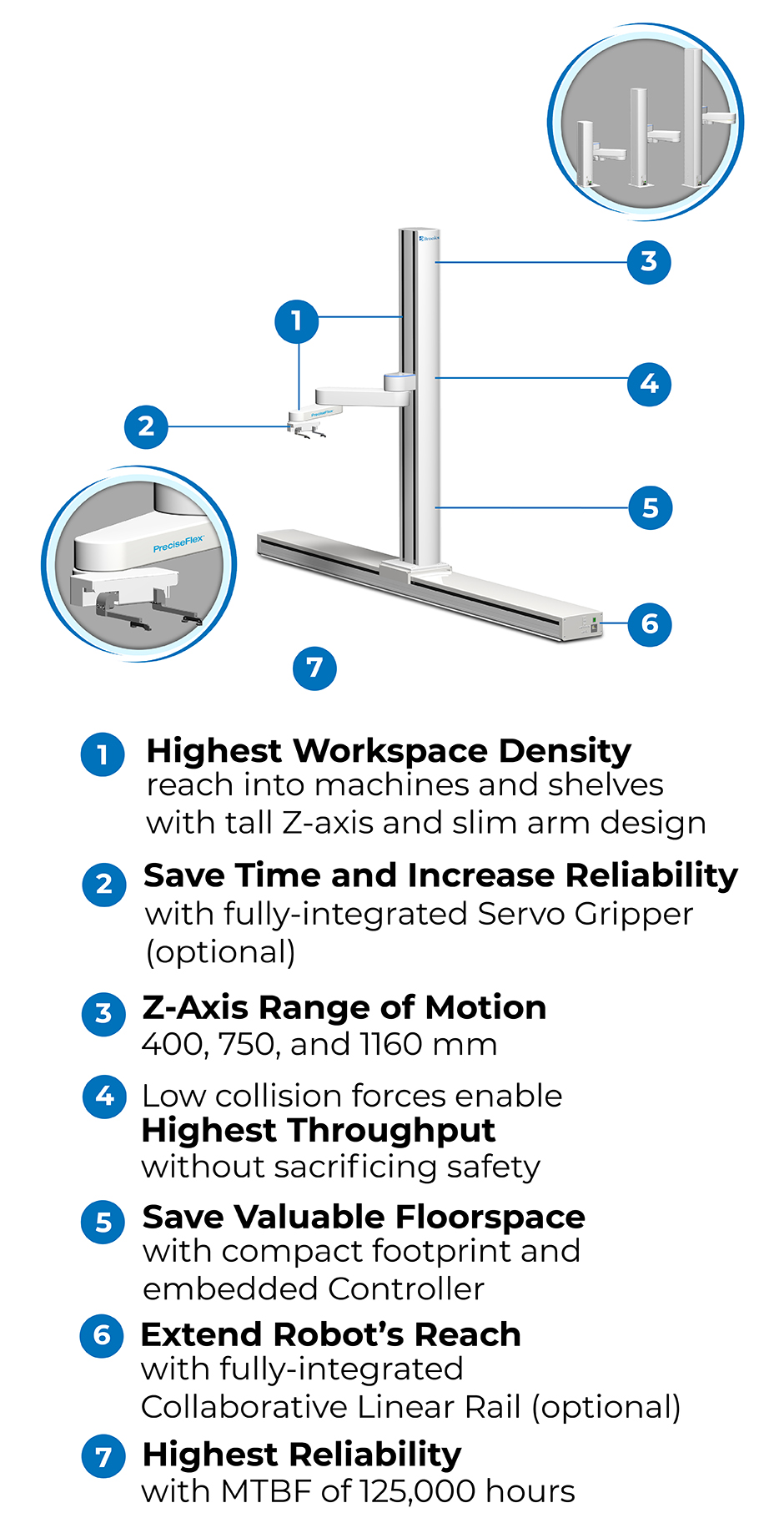

The PreciseFlex 3400 collaborative robot is ideal for many small parts handling and assembly applications delivering the highest reliability available.

Available with 400, 750, and 1160 mm vertical reach, the cylindrical column work envelope keeps the footprint small and enables reaching into shelves, racks, and machines.

Industrial applications include Machine Tending, Part Transfer / Pick & Place, PCA Handling & Test, Small Parts Handling, Agricultural Picking/Pruning, and Mobile collaborative robots.

Lab Automation applications include Pathology, Liquid Sampling, Sample Handling, Specimen Sorting, Modular Lab Automation, and Mobile collaborative robots.

Get Started

The optional collaborative linear rail extends the reach of the robot by 1.0, 1.5, or 2.0 meters. Our linear rail is inherently collaborative.

With their space-saving footprint and highest workspace density, PreciseFlex robots make the most of your floor space. The controller is embedded in the robot, and there are no bulky robot cables to deal with. Additionally, PreciseFlex robots can reach into shelves and racks from top to bottom providing access to stacked parts. allow you to stack parts in shelves and racks, further reducing the system footprint.

Our optional servo grippers also make starting applications faster and easier.

Get Started

download DAtasheet